Nickel Flanges Specification :

ASTM B564 / ASME SB564

Nickel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Kvn Steels is a well-known industry in the global market and is today dealing to a greater extent with its esteem global and local clients. We today are fully involved in manufacturing and distributing the superior quality of Nickel 200/201 Flanges to our valuable clients. These nickel 200 flanges and nickel 201 flanges are designed by using superior quality of alloy and as per the set production norms. Our clients can collect the same from us at various specifications and standards, dimensions, class/pressure, face types, and sizes. Also, they can collect the same from us at customized specifications according to their demands. Our product too confirms industry quality standards like ASTM, ASME, ANSI, EN, DIN, BS, etc.

The types of Nickel 200/201 Flanges that our clients can collect from us is slip-on flanges, threaded flanges, weld neck flanges, socket weld flanges, blind flanges, reducing flanges, lap joint flanges, plate flanges, orifice flanges, forged flanges, ring type joint flanges, tongue & groove flanges, nipo flanges, screwed flanges, male & female flanges, raised face flanges and square flanges.

Nickel 200 and 201 alloy is the solid solution strengthened and a commercially pure wrought material that is having very good mechanical properties over different temperatures. Also, it is having very good resistance ability to several corrosives, especially in hydroxides. Nickel 201 is the modification to 200 for controlling the carbon that at the temperature ranging of 600 deg F – 1400 deg F keep it being embrittled by the intergranular precipitate.

ASTM B564 Nickel 200 / 201 Blind Flanges Exporter, Alloy ASTM B564 201 Long Weld Neck Flanges, Nickel 200 Ring Type Joint - RTJ Flanges, Nickel® 200 Flanges, ASTM B564 Nickel 200 / 201 Flanges Supplier, Nickel 200 / 201 Weld Neck Flanges, Nickel 201 Slip on Flanges, Alloy 200 / 201 Flanges Manufacturer in India.

Alloy DIN 2.4068 Spectacle Blind Flanges Dealer, ASTM B564 Nickel® 201 SORF Flanges, 200 Nickel Threaded Flanges Stockists, Nickel UNS N02201 Plate Flanges, DIN 2.4066 Pipe Flanges, UNS N02200 Socket Weld Trader, ASME SB564 Nickel 200 / 201 Flanges Supplier in India.

Our manufactured ranges of Nickel 200/201 Flanges are having many good properties to offer and it has become possible because of the effective use of 100% pure Nickel 200/201 alloy for its fabrications. The properties are caustic alkalis resistant, reducing chemical resistance, electrical conductivity, heat resistant, good megnetostrive properties sulfuric and hydrochloric acid resistance.

The applications where Nickel 200/201 Flanges is seen used are heat exchangers, condensers, petrochemicals, specialty chemicals, automotive industry, chemical industry, pulp & paper industry, etc.

Nickel 200/201 Flanges is thoroughly quality tested to make sure that only good quality of product gets dispatched. Therefore the tests done are IGC tests, PMI tests, chemical tests, etc.

Nickel 200 / 201 Flanges Equivalent Grades

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

| Nickel 201 | N02201 | 2.4068 | NW 2201 | LC-Ni 99 |

Alloy 200 / 201 Slip On Flanges

Nickel® 200 SORF Flanges, UNS N02200 / N02201 Slip On Flanges, DIN 2.4066 SORF Flanges, ASME SB 564 Alloy 201 Slip-on Raised Face Flanges

Nickel 200 / 201 Weld Neck Flanges

ASME SB564 Nickel 200 WNRF Flanges, ASTM B564 Nickel® 201 Weld Neck Flanges, DIN 2.4066 Weld Neck Flanges, UNS N02200 Weld Neck Raised Face Flanges

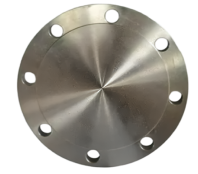

Alloy 200 / 201 Blind Flanges

ASTM B564 Nickel 200 Blind Flanges, UNS N02200 / DIN 2.4066 Blind Flanges, ASME SB564 Alloy 201 BLRF Flanges, Alloy 200/201 Blind Raised Face Flanges Supplier

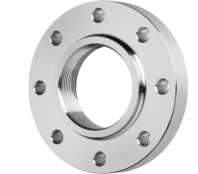

Alloy 200/201 Threaded Flanges

DIN 2.4066 Threaded Flanges, UNS N02200 Screwed Flanges, ASME SB 564 Alloy 201 Threaded Flanges, ASTM B564 Nickel 201 Threaded Flanges

Alloy 200/201 Socket Weld Flanges

ASTM B564 201 Nickel Socket Weld Flanges, Nickel UNS N02200/ N02201 Socket Weld Flanges, Alloy DIN 2.4068 Socket Weld Flanges

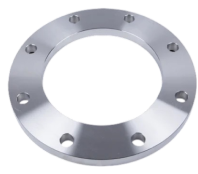

Nickel 200/201 Lap Joint Flanges

UNS N02200 Lap Joint Flanges, Nickel® 200 Lap Joint Flanges, ASTM B564 201 Nickel Lap Joint Flanges, ASME SB564 Nickel Alloy 200/201 Lap Joint Flanges

Alloy 200/201 Ring Type Joint Flange

UNS N02200 Ring Type Joint Flange, ANSI B16.5 Nickel 200 RTJ Flanges, ASTM B564 Nickel 201 Ring Type Joint Flanges, ASME SB564 Alloy 200/201 Ring Type Joint Flanges

Nickel 200/201 Orifice Flanges

UNS N02200 Orifice Flanges, B16.36 Nickel 200 / 201 Orifice Flanges, ASTM B564 Alloy 200 Orifice Flanges, ASME SB 564 Nickel Alloy 200/201 Orifice Flanges

Alloy 200/201 Long Weld Neck Flanges

UNS N02201 Long Weld Neck Flanges, Nickel 2.4068 Long Weld Neck Flanges, ASTM B564 Nickel 201 Long Weld Neck Flanges, ASME SB 564 Nickel 201 Long Weld Neck Flanges

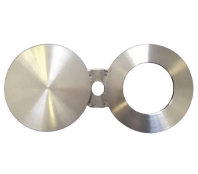

Nickel 200/201 Spectacle Blind Flanges

UNS N02201 Spectacle Blind Flanges, ANSI / ASME B16.5 Alloy 201 Spectacle Blind Flanges, ASTM B564 Alloy 200/201 Spectacle Blind Flanges, ASME SB 564 Nickel 200/201 Spectacle Blind Flanges

Nickel 200/201 Forged Flanges

UNS N02201 Forged Flanges, B16.5 Alloy 200 Forged Flanges, ASTM B564 Nickel Alloy 201 Forged Flanges, ASME SB564 Alloy 200/201 Forged Flanges

Nickel 200/201 Plate Flanges

UNS N02200 Plate Flanges, ANSI B16.5 Nickel 200/201 Plate Flanges, ASTM B564 Nickel 200/201 Plate Flanges, ASME SB564 Nickel Alloy 201 Plate Flanges

Nickel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Nickel 200 / 201 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200 / 201 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel 201 0.02 max 0.35 max 0.35 max 0.01 max 0.25 max 0.40 max 99.0 min

Physical Properties of Nickel 200/201 Flanges

| Density (Kg.m-1) | 84.3 |

|---|---|

| Magnetic Permeability (20°C) | <1.005 |

| Curie Temperature (°C) | -90 |

| Young’s Modulus (N/mm2) | 179 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 418 |

| Specific Electrical Resistance, 20°C (?O.m) | 0.62 |

| Thermal conductivity,20°C (W.m-1.°K-1) | 17.5 |

| Mean coefficient of thermal expansion, 20-100°C (°K-1) | 13.4 x 10-6 |

Our Nickel 200/201 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry