Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

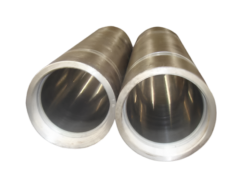

KVN Steels stands as a prominent name in the production, supply, and global export of Alloy Steel P5 Pipes and Tubes, delivering customized solutions tailored to meet specific customer requirements. With years of industry expertise, our highly skilled and trustworthy team ensures top-tier service and consistent quality that meets international standards.

Alloy Steel P5 Pipes are broadly categorized into high-alloy and low-alloy variants, enabling clients to select the optimal material grade for their application. Known for their compact structure, high durability, precise engineering, and excellent mechanical strength, these pipes stand out in performance and value. Available in a wide array of grades and dimensions, they offer exceptional functionality even under the most demanding operational environments due to their superior resistance to heat and corrosion.

Our inventory includes industry-recognized standards such as, ASTM S/A 335 Alloy Steel P5 Seamless Pipes, Chrome Moly P5 Pipe, UNS K41545 & DIN 1.7362 Seamless Pipes, EN X11CrMo5 Grade Tubing & Alloy 5Cr-½Mo & A/SA 335 GR. P5 Pipes.

Applications Across Critical Industries

Alloy Steel P5 Pipes & Tubes are widely used across diverse industries including, Offshore Drilling & Oil Extraction, Thermal and Nuclear Power Generation, Petrochemical and Gas Processing Units, Chemical Manufacturing & Equipment, Pharmaceuticals and Biomedical Equipment, Seawater Desalination Plants, Heat Exchangers and Condensers, Pulp & Paper Manufacturing.

Thanks to their corrosion-resistant and high-temperature endurance properties, these pipes are ideal for deep-sea drilling operations, long-distance fluid transport, and high-pressure applications. Their robustness allows them to withstand extreme thermal conditions, making them suitable for flanging, bending, welding, and other forming operations, particularly in energy and petrochemical infrastructures. Their non-reactive nature also renders them reliable in chemically aggressive environments and pharmaceutical manufacturing.

Quality Assurance & Documentation

Each product, whether Steel P5 Pipes & Tubes or Steel P9 Pipes & Tubes, undergoes a thorough inspection process, including mechanical testing, flattening and bending tests, as well as micro and macro structural analysis.

We ensure all materials are accompanied by complete test reports and certifications. Moreover, we adhere to strict packaging protocols to safeguard the integrity of the pipes during storage and transit.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P5 | 1.7362 | K41545 | X11CrMo5 |

Alloy Steel P5 Seamless Pipes

ASTM A/SA 335 Gr. P5 Alloy Steel Seamless Pipe, UNS K41545 Seamless Pipes, DIN 1.7362 Seamless Pipes, Grade P5 Seamless Alloy Steel Pipe, Alloy Steel 5Cr-1/2Mo Pipes

Chrome Moly P5 Seamless Pipes

CrMo P5 Seamless Pipes, P5 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P5 Chrome-Moly Seamless Pipe, Chrome Moly 5Cr-1/2Mo Seamless Pipes

Alloy Steel P5 High Pressure Pipes

ASTM A335 P5 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P5 Boiler Pipes Exporter, ASME SA 335 Grade P5 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Alloy Steel P5 Seamless Pipes And Tubes

| Grade | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P5 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.45-0.65 |

Mechanical Properties Of ASME SA335 Alloy Steel P5 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P5 | 415 min | 205 min | 30 min |

Our Alloy steel P5 Pipes & Tubes are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry